Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Nota: This feature may not be available in some browsers.

Je gebruikt een verouderde webbrowser. Het kan mogelijk deze of andere websites niet correct weergeven.

Het is raadzaam om je webbrowser te upgraden of een alternatieve webbrowser te gebruiken.

Het is raadzaam om je webbrowser te upgraden of een alternatieve webbrowser te gebruiken.

Zeehaen - 1:37.5 - From Dutch Explorer Abel J. Tasman

- Topicstarter Marcus Botanicus

- Startdatum

-

- Tags

- abel tasman fluit zeehaen

O

Je kan van een plaatje aluminium een mal maken welke je op je plank legt om zo de plank af te tekenen. Door de mal om te draaien kan je 2 planken exact passend op elkaar krijgen.

Ander woord voor butts?daar waag ik mij niet aan.

I don't have any aluminum, just brass and copper.

I knew that when I asked about another word for butts, I was going to get comments such as yours.

Hoosterw,

You're corrects about the definition, callex scarf joi ts.

Marcus

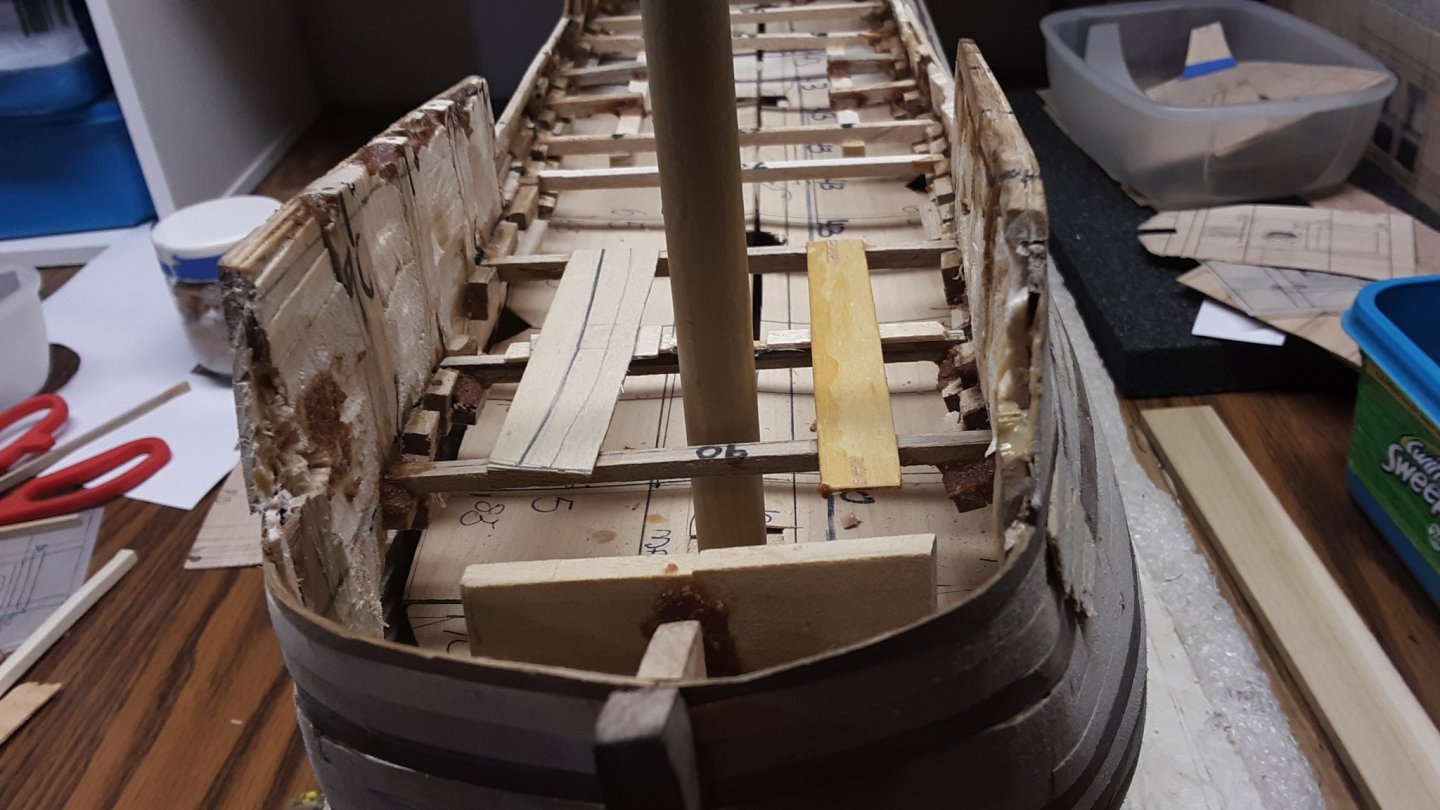

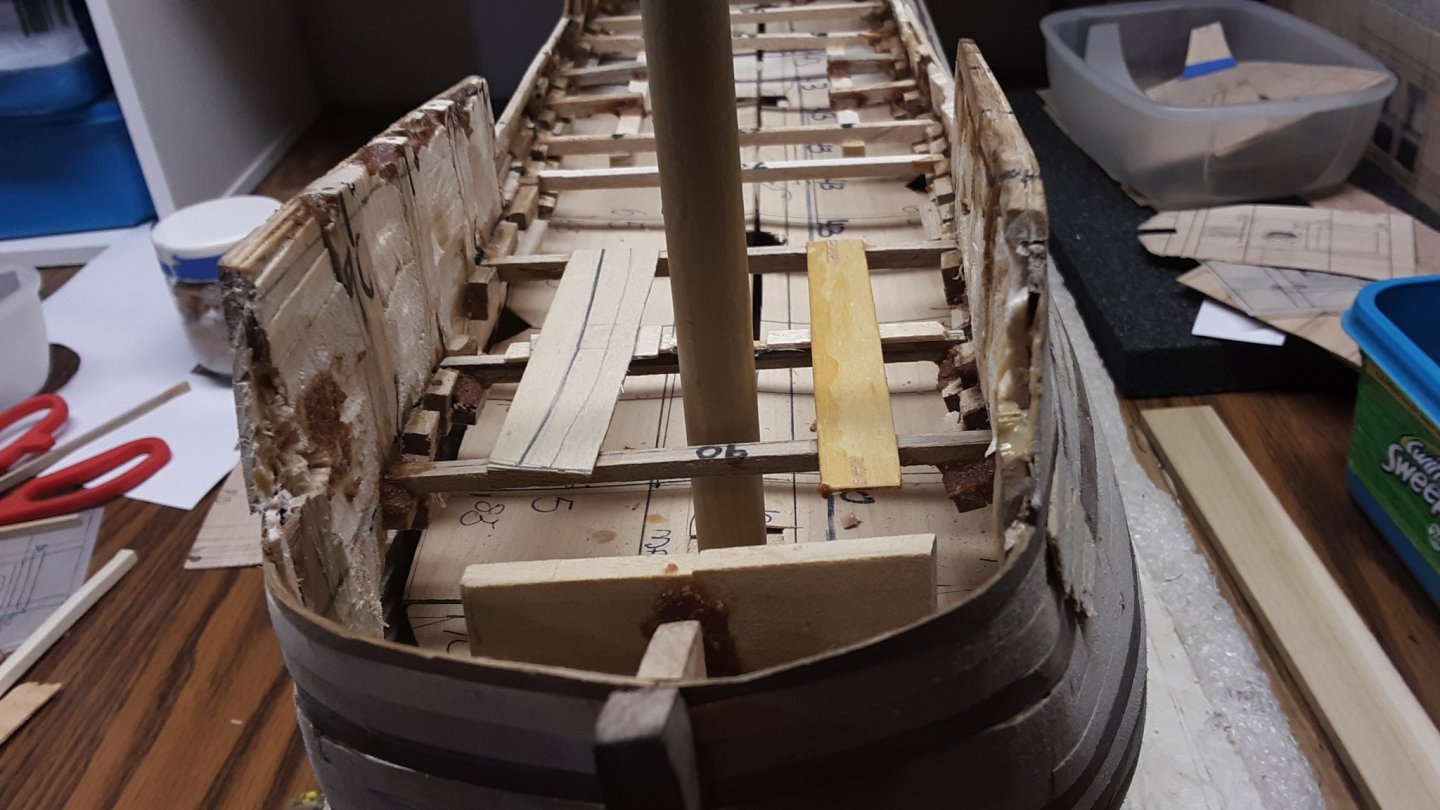

Worked on the bow most of the day. Figuring and creating a bowsprite holder.

Strengthening the deck.

Glued deck in place.

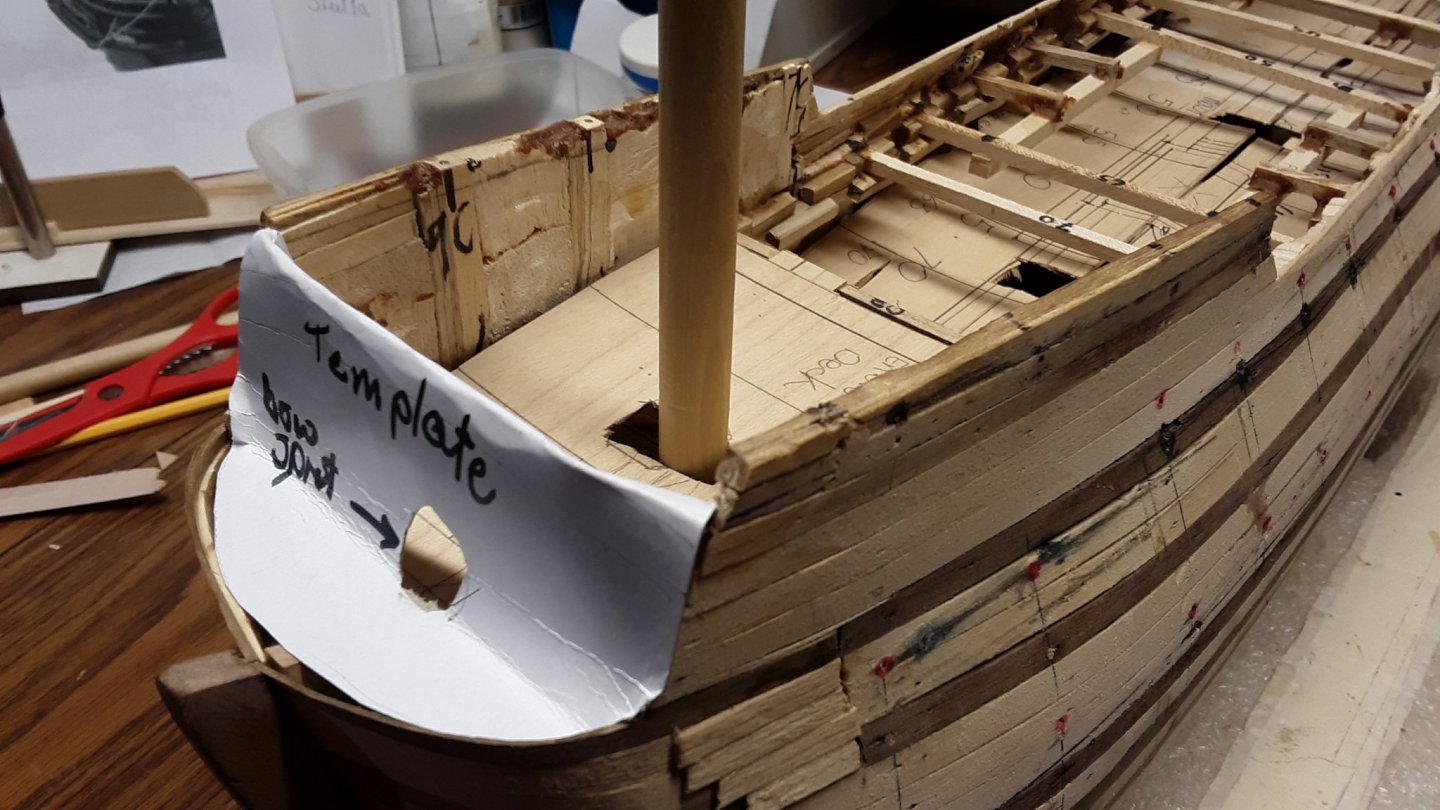

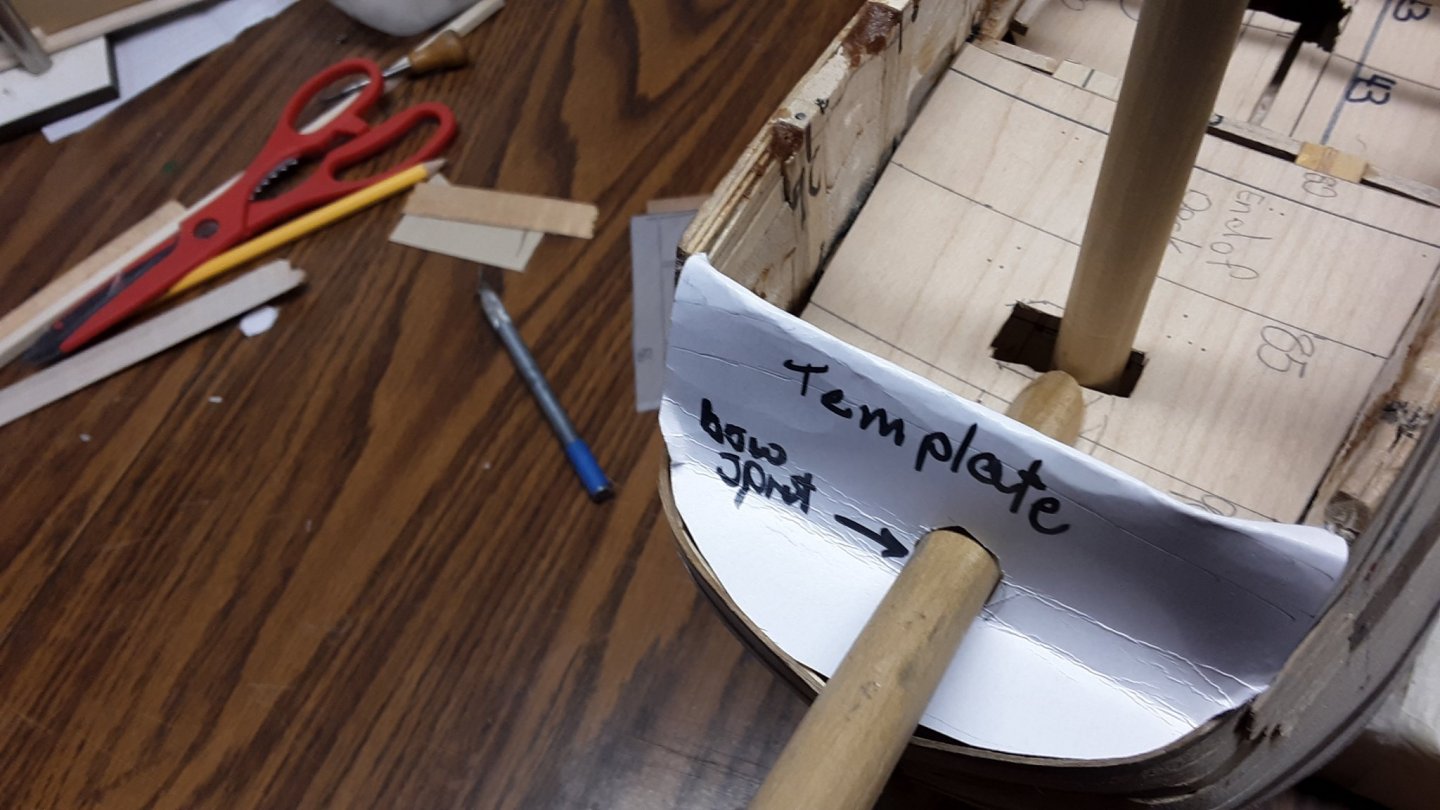

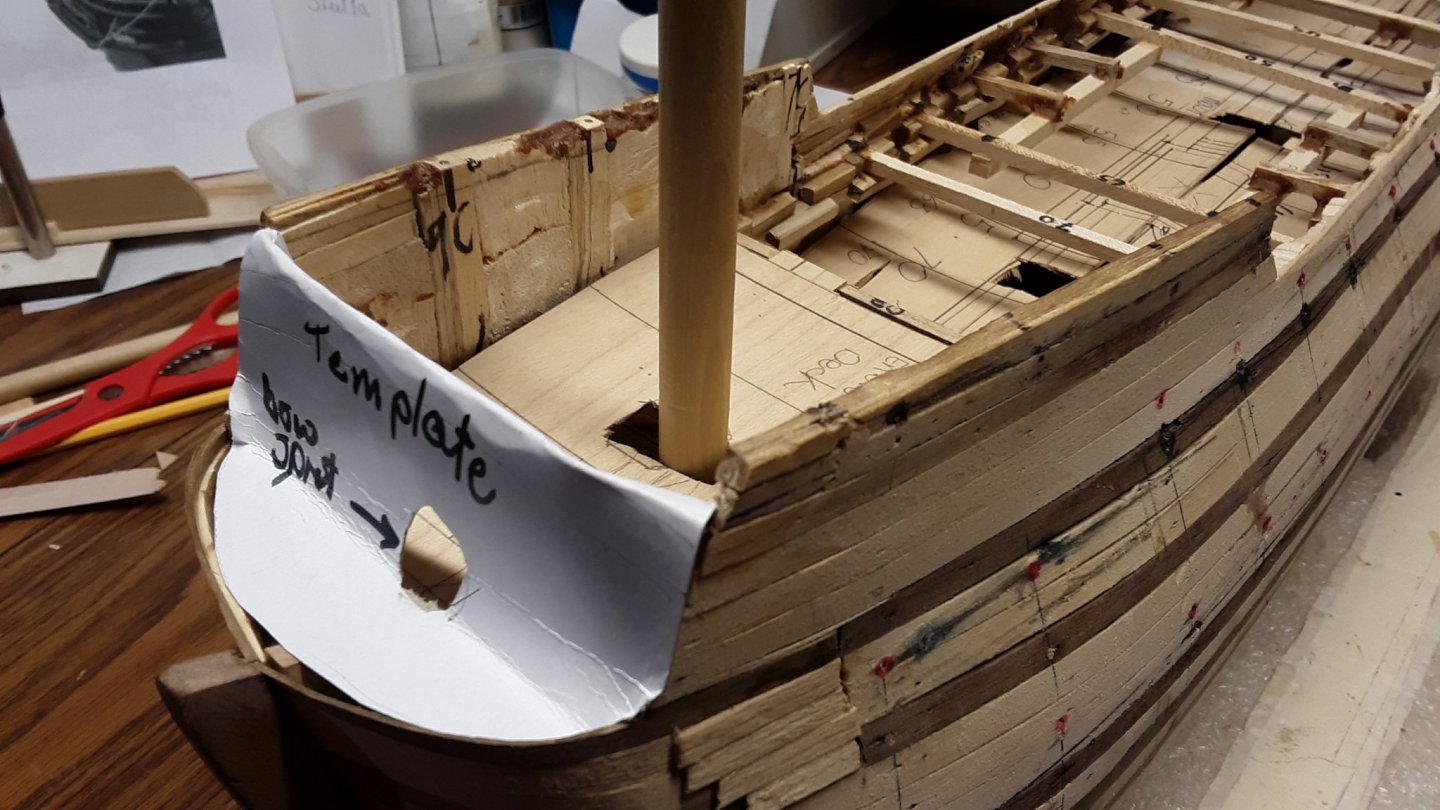

Used card to make a template of where the bowsprite goes.

With a hand drill, drilled a hole through the bowsprite, deck and part of the wood. The drill bit kept it all in place while i could draw the lines for the holder.

The area where the bowsprite goes into the ship, is there a name for that area?

Bowsprite holder.

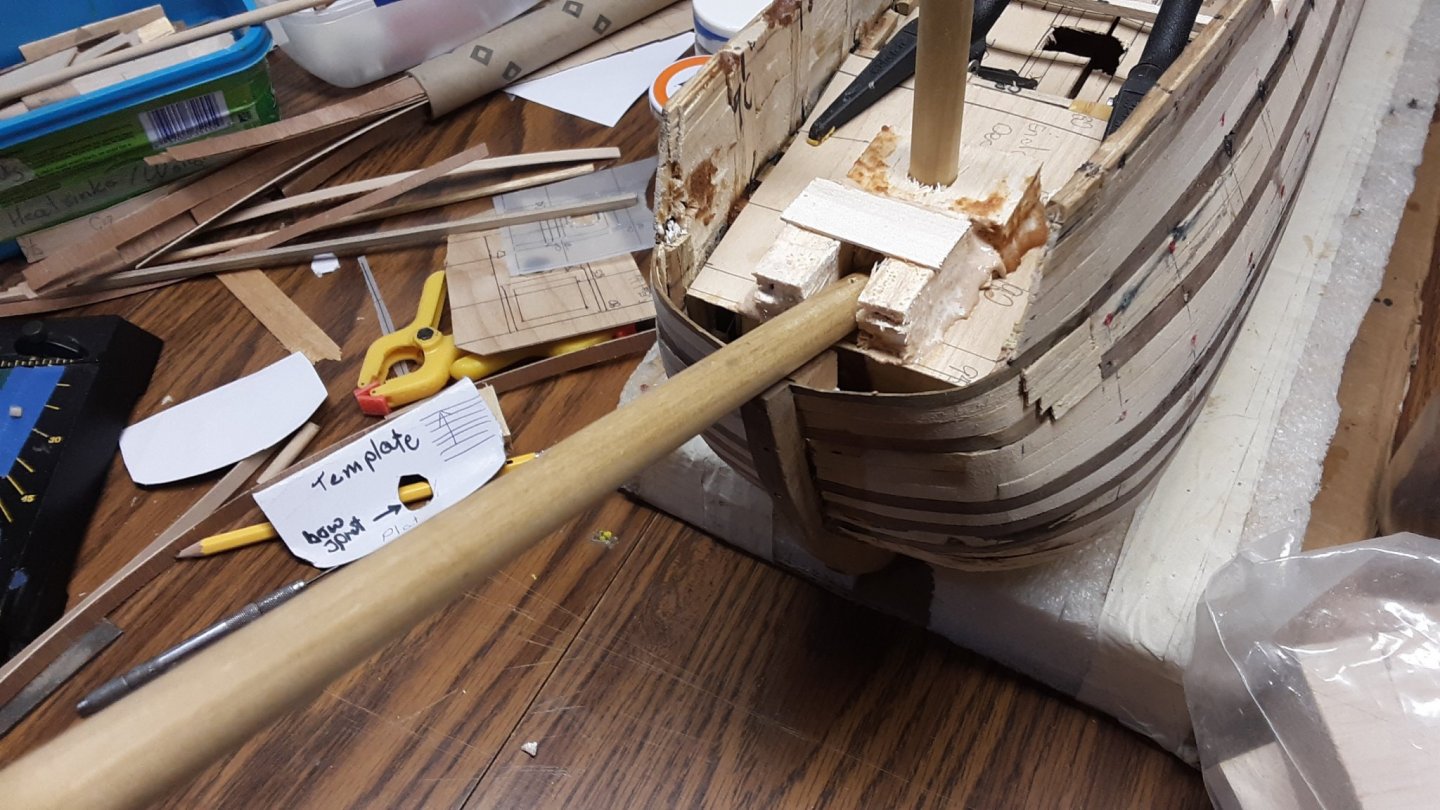

Dry fit planking and bowsprite.

Once i have planked that area and made a hole in it, I can slide the bowsprite with some glue into the holder.

Marcus

Strengthening the deck.

Glued deck in place.

Used card to make a template of where the bowsprite goes.

With a hand drill, drilled a hole through the bowsprite, deck and part of the wood. The drill bit kept it all in place while i could draw the lines for the holder.

The area where the bowsprite goes into the ship, is there a name for that area?

Bowsprite holder.

Dry fit planking and bowsprite.

Once i have planked that area and made a hole in it, I can slide the bowsprite with some glue into the holder.

Marcus

Pingu,

Thanks for the definition.

In general this is one of the things I like about this site. Everyone takes the time to tell me what the Dutch definitions are for parts of a ship.

Marcus

Thanks for the definition.

In general this is one of the things I like about this site. Everyone takes the time to tell me what the Dutch definitions are for parts of a ship.

Marcus

Thank you for all the likes.

Finishing up on the location of where the bowsprite goes into its holder and the little deck located at the tip of the stem.

Started working on the bowsprite panel. Cut a piece of veneer by 0.5mm wider than the actual location of the panel so it is both a tight fit and slightly bowed or curved. Started paneling the veneer with 5mm wide cherry strips.

I still need to raise the wall from hull by 4mm. So then it is even with the other side.

Bowsprite panel can be removed for easy adding 2 cathead squares, 1 gunprt and 3 steps.

Once the glue dried the paneling was marked for the catheads and gunport.

Gunport has been cut out. Tomorrow the 2 cathead squares will be removed.

Marcus

Finishing up on the location of where the bowsprite goes into its holder and the little deck located at the tip of the stem.

Started working on the bowsprite panel. Cut a piece of veneer by 0.5mm wider than the actual location of the panel so it is both a tight fit and slightly bowed or curved. Started paneling the veneer with 5mm wide cherry strips.

I still need to raise the wall from hull by 4mm. So then it is even with the other side.

Bowsprite panel can be removed for easy adding 2 cathead squares, 1 gunprt and 3 steps.

Once the glue dried the paneling was marked for the catheads and gunport.

Gunport has been cut out. Tomorrow the 2 cathead squares will be removed.

Marcus

Laatst bewerkt:

Thank you for all the likes.

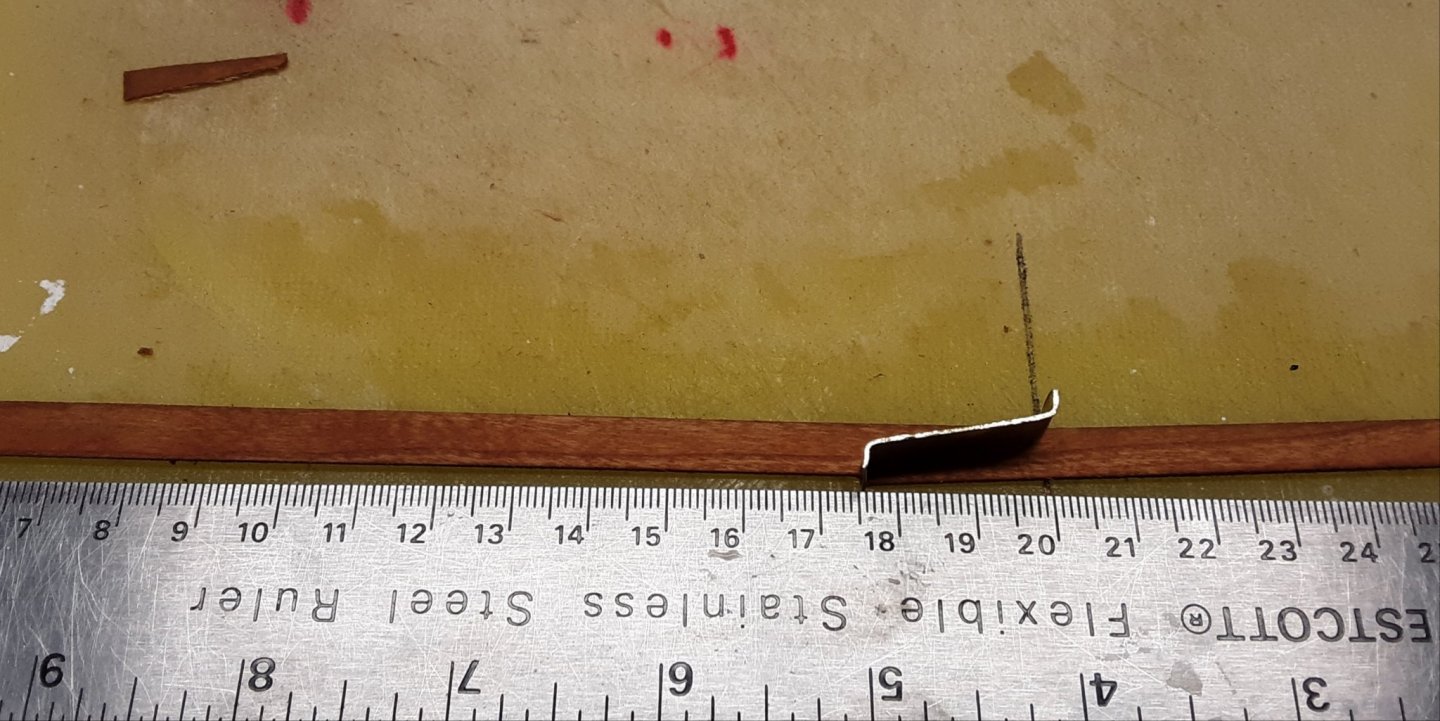

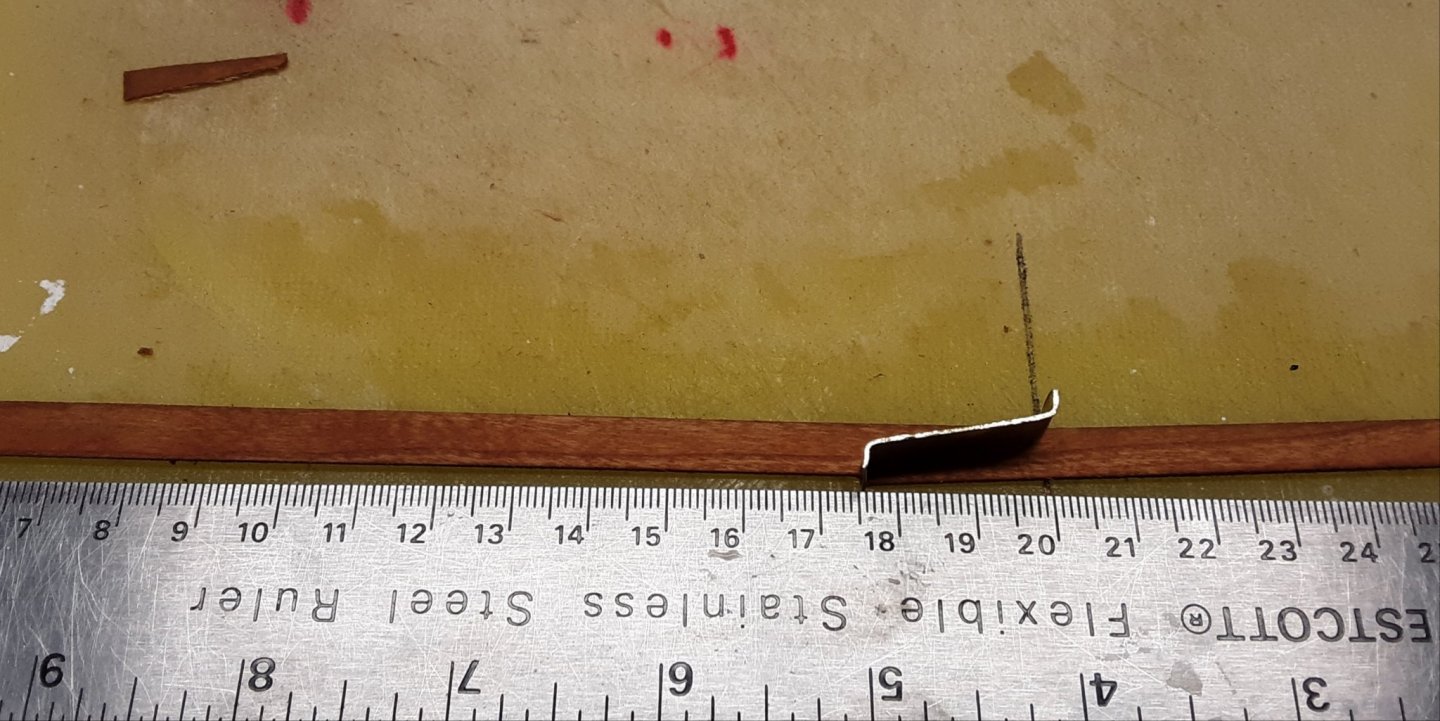

Preparing the second layer of cherry planking. Most of the planks will be 20 cm long with a Dutch scarph joint on each side. There will also be smaller lengths.

Put the planks in some water as they will cut better without splitting. Once the scarphs are cut the planks will be dried.

Top plank is to show what the scarphs look like when cut.

Middle plank is to show when the scarphs are together.

Bottom plank being cut to make a scarph.

Close up from a scarph being created.

I will be creating joints on about 80 planks. Not all joints will be created now, some will be made when I plank the ship.

Marcus

Preparing the second layer of cherry planking. Most of the planks will be 20 cm long with a Dutch scarph joint on each side. There will also be smaller lengths.

Put the planks in some water as they will cut better without splitting. Once the scarphs are cut the planks will be dried.

Top plank is to show what the scarphs look like when cut.

Middle plank is to show when the scarphs are together.

Bottom plank being cut to make a scarph.

Close up from a scarph being created.

I will be creating joints on about 80 planks. Not all joints will be created now, some will be made when I plank the ship.

Marcus

#Peter,

Ik weet wel zeker dat ik elke plank een correctie moet geven als ik de lijnen van het schip volg.

#amazone,

Dat is aardig wat werk. Dat heb ik gedaan op de Boyer. Ik legde de plank einden op elkaar op de romp en met mes en lineaal de lippen maken.

Marcus

Ik weet wel zeker dat ik elke plank een correctie moet geven als ik de lijnen van het schip volg.

ik zaag of snij ze nog altijd 1 voor 1 uit

#amazone,

Dat is aardig wat werk. Dat heb ik gedaan op de Boyer. Ik legde de plank einden op elkaar op de romp en met mes en lineaal de lippen maken.

Marcus

Thanks for all the comments and likes.

I could not wait till Monday so I did a strake next to the keel. Started with a straight butt beginning at the lowest wale and continued with the Dutch scarphs. Used 4 pieces of 20cm long cherry planks and a little piece to finish the strake.

Creating joints when the wood is wet, let the planks completely dry and then glue them together on the hull works well.

Marcus

I could not wait till Monday so I did a strake next to the keel. Started with a straight butt beginning at the lowest wale and continued with the Dutch scarphs. Used 4 pieces of 20cm long cherry planks and a little piece to finish the strake.

Creating joints when the wood is wet, let the planks completely dry and then glue them together on the hull works well.

Marcus

Stephan Kertész

Forum veteraan

Nou ben benieuwd.

This is what Ab Hoving said.

Marcus

Don't you think it would be wise to mark the lines of the bottom, the bilges and the lower wale on the hull before applying any strakes? That way you can monitor the various widths of the planking to avoid nasty corrections higher up the hull.

The bottom is roughly 2/3 of the total width, the top of the bilges were mostly reached with three (sometimes 4) strakes. The position of the lower wale is there already, but has to be fine-tuned to ensure a fluent line. This is essential!

Ab

Ik doe nooit wat Ab zegt. Ik gok alles en het lukt aardig en dat is te zien aan mijn Boyer. Alle lijnen lopen mooi. Ik weet wel hoe het moet en heb het vroeger met een boot gedaan, daarna niet meer.

Misschien is het beter dat ik het meet een fluit doe vanwege dat alle planken rara bochten maken.

Niks bouwen en de boeken erbij.

Marcus

Marcus

Don't you think it would be wise to mark the lines of the bottom, the bilges and the lower wale on the hull before applying any strakes? That way you can monitor the various widths of the planking to avoid nasty corrections higher up the hull.

The bottom is roughly 2/3 of the total width, the top of the bilges were mostly reached with three (sometimes 4) strakes. The position of the lower wale is there already, but has to be fine-tuned to ensure a fluent line. This is essential!

Ab

Ik doe nooit wat Ab zegt. Ik gok alles en het lukt aardig en dat is te zien aan mijn Boyer. Alle lijnen lopen mooi. Ik weet wel hoe het moet en heb het vroeger met een boot gedaan, daarna niet meer.

Misschien is het beter dat ik het meet een fluit doe vanwege dat alle planken rara bochten maken.

Niks bouwen en de boeken erbij.

Marcus

Je lijkt wel een 17e eeuwse bouwmeester....Niks bouwen en de boeken erbij.

Is there a site or book that has the translation in Du - En and En - Du of ship words. When I read the different builds on this site there are many words I have to look up either in my van Dale (I have both books) or google translate.

Thanks

Marcus

Thanks

Marcus

Heb nog ergens een document met de meeste termen in NL-EN-IT en volgens mij ook Frans. Moet wel ff goed gaan zoeken en dan omzetten naar pdf

Stephan Kertész

Forum veteraan

Er is ook een site met allemaal scheepstermen. Ik weet effe niet meer welke. Iets met binnenvaart of zo.

Heb hem

https://www.vaartips.nl/tipu.htm

Heb hem

https://www.vaartips.nl/tipu.htm

Laatst bewerkt:

Dat zou mooi zijn.Heb nog ergens een document met de meeste termen in NL-EN-IT en volgens mij ook Frans. Moet wel ff goed gaan zoeken en dan omzetten naar pdf